Subscribe to the Franka Community Newsletter for the latest news and insights.

Subscribe to the Franka Community Newsletter for the latest news and insights.

ABOUT FRANKA

EMPOWERING INNOVATORS,

ENABLING BREAKTHROUGHS

ENABLING BREAKTHROUGHS

Franka Robotics is a German, research-driven robotics company headquartered in Munich and operating globally. Founded in 2016, it is part of Agile Robots since 2023.

Our mission is to enable the growing community of robotics and AI professionals to shape a pivotal moment in human evolution: giving AI a robot body. We achieve this by developing the reference robotics platform that facilitates big-thinkers to explore, collaborate, create and share – thereby driving continuous advancements in robotics and AI.

Franka Robotics’ endeavor is contributing to a bright future where capable AI-powered robots coexist and work alongside us, enhancing everyone’s lives and progressing society.

AI SERVICES AND UPCOMING PRODUCTS

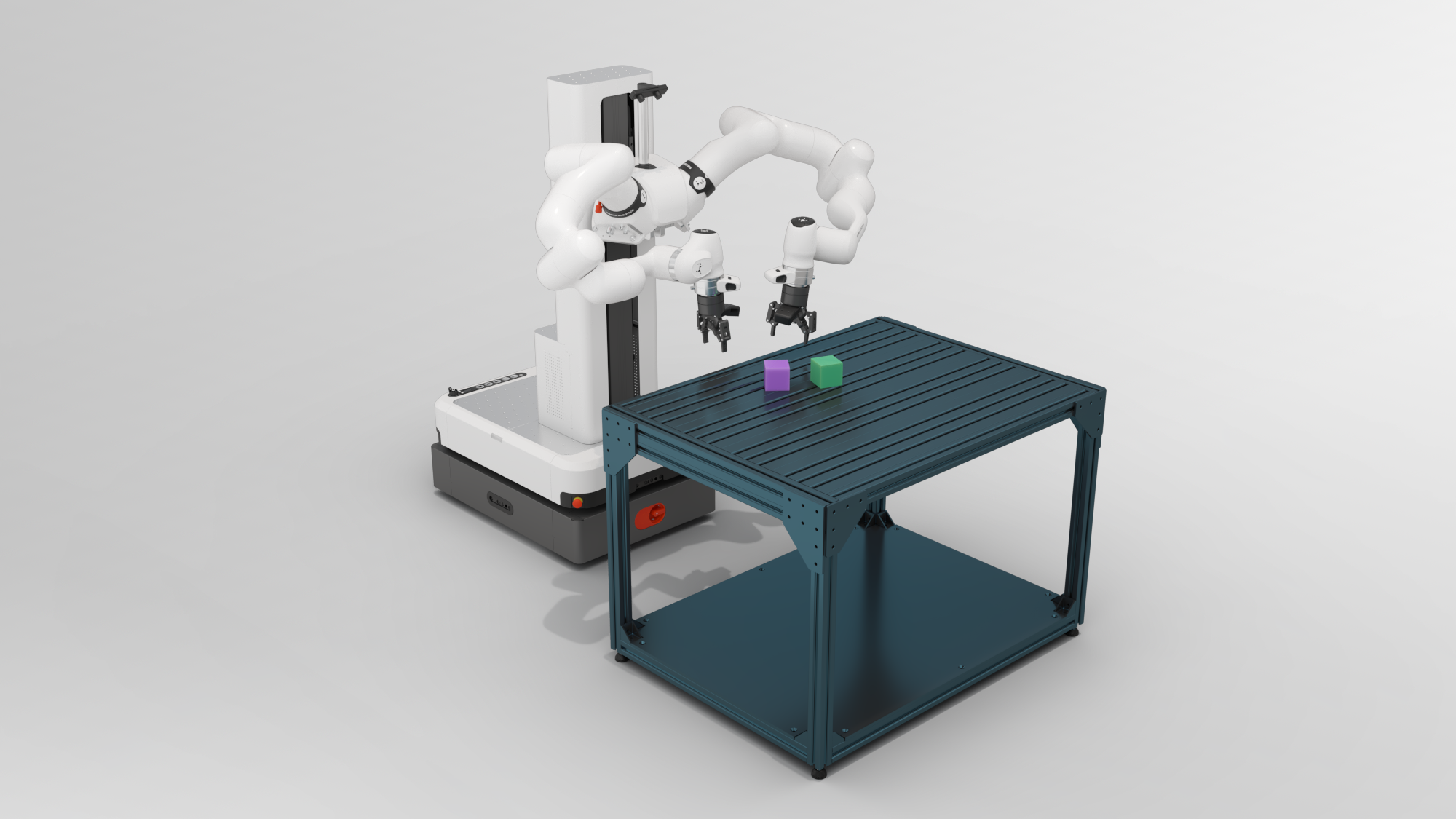

THE REFERENCE PLATFORM FOR EMBODIED AI

A new generation of robot systems designed to enable physical intelligence research, from tactile teleoperation to mobile manipulation. These systems support upcoming AI services, including data collection at scale and real-world learning.

ANNOUNCEMENT

FRANKA ROBOTICS INTEGRATES DIANA 7 BY AGILE ROBOTS

Franka Robotics has announced that the robot Diana 7 by Agile Robots now supports the Franka Control Interface (FCI). This development paves the way for its application in research and academia. As a result, Franka Robotics has now added Diana 7 to its ecosystem, expanding its portfolio with a robot featuring greater reach and payload capacity.

FROM THE FRANKA COMMUNITY

COMMUNITY HIGHLIGHTS

A selection of highlights from the Franka Community, from groundbreaking research in robotics and AI to practical applications and educational resources.

-

METAAdvancing robotics and touch perception

METAAdvancing robotics and touch perception -

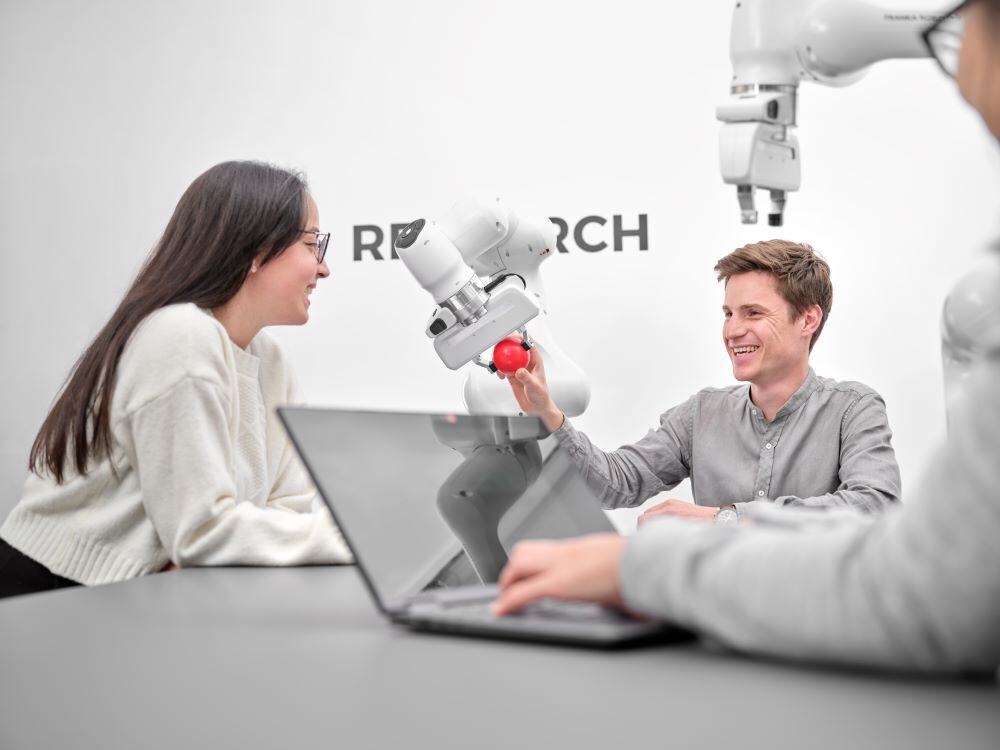

TOYOTA RESEARCH INSTITUTETeaching robots new behaviours

TOYOTA RESEARCH INSTITUTETeaching robots new behaviours -

MITProvably safe and efficient motion planning with uncertain human dynamics

MITProvably safe and efficient motion planning with uncertain human dynamics -

TSINGHUA UNIVERSITYLearning pregrasp manipulation of objects from ungraspable poses

TSINGHUA UNIVERSITYLearning pregrasp manipulation of objects from ungraspable poses -

DROIDA large-scale in-the-wild robot manipulation dataset

DROIDA large-scale in-the-wild robot manipulation dataset -

QUTReactive base control for on-the-move mobile manipulation in dynamic environments

QUTReactive base control for on-the-move mobile manipulation in dynamic environments -

UNIVERSITY OF TORONTOORGANA: A robotic assistant for mautomated chemistry experimentation and characterization

UNIVERSITY OF TORONTOORGANA: A robotic assistant for mautomated chemistry experimentation and characterization -

TU DRESDENRobot-assisted surgery / human-machine interaction in the OR

TU DRESDENRobot-assisted surgery / human-machine interaction in the OR